Construction in Australia as in other parts of the world is considered an essential business. In 2019, over 1.15 million people were employed in construction, that is 9.2% of all jobs in Australia. The construction industry contributes to 9% of the total GDP of the country, and it will be key to the recovery of the national economy.

The introduction of heavy machinery like cranes, excavators and bulldozers transformed the industry, but automation has yet to play a more important role in the industry. Construction is one of the three industries (together with agriculture and transport) that are slow to embrace digital technologies and innovations; as a result, there is a number of opportunities emerging for businesses providing services to the construction industry. In a highly digital age, almost every aspect of the industry can be supported by innovative new technologies.

Drones and robots are being utilised to automate aspects of the maintenance process itself directly, and advanced sensors combined with the application of machine learning algorithms are enabling highly accurate predictive servicing. In a recent example of this, Data61 have utilised machine learning to create a model that can identify water mains at risk of potential failure. This model will allow Sydney Water to be proactive about their maintenance requirements and has the potential to save them $700 million in reactive repairs and maintenance.

"From navigating dangerous mines to spotting toxic leaks in nuclear power plants, Australian-made robots are set to change life as we know it." - @TheNewDailyAu sat down with us to discuss #Australia's #robotics #industry and its incredible capabilities: https://t.co/KmcyyjTv4W pic.twitter.com/ccUstEcKp1

— Data61 (@Data61news) March 13, 2020

In a 2019 study, McKinsey Australia identified the Construction industry as one of the nine sectors most exposed to automation opportunity and estimates that 25 per cent of work activities will be automated by 2030. This automation will be achieved through the application of new technologies, which in many cases will lead to new servicing and maintenance requirements. The lack of technology in construction maintenance presents an excellent opportunity to generate business in an industry that will remain one of the strong pillars of Australia. Automation has the potential to add $2.2 trillion to the Australian economy over the next 15 years.

Across the globe, we’re seeing technology being successfully implemented to improve the safety and efficiency of maintenance procedures. In 2018, Enes Karaaslanat led a study at the University of Central Florida that focused on developing a human-centred tool to offer improvements to infrastructure inspection and maintenance practices. They created an augmented reality (AR) framework that is intended to be integrated into a wearable headset, allowing an inspector to automatically analyse components they observe in real-time, and obtain information about any defects present. This technology greatly empowers maintenance inspectors and increases their ability to accurately identify potential threats in infrastructure.

Here in Australia, the Centre for Autonomous Systems (CAS) at the University of Technology Sydney worked in partnership with the NSW Roads and Maritime Services (RMS) to create a robot that is intended to inspect hazardous or inaccessible regions of the Sydney Harbour Bridge.

The robust device is capable of navigating complex terrain that is usually difficult or dangerous for humans to access and collects valuable information about the condition of a structure. Through this automation, the RMS has greatly increased the efficiency of their maintenance process, while also removing the associated occupational health and safety risks that come with human workers surveying these areas.

With the Construction industry in Australia projected to be a crucial factor on the recovery of our economy, and with high-tech equipment and automation at the core of this growth, it appears that there will be an increasing demand for machinery maintenance services in the coming years. In order to cater to this demand, and capitalise on emerging opportunities, it is essential for companies providing automation in the Maintenance for the Construction industry to implement new technologies to improve their own productivity. With this in mind, let’s explore the 5 keys to performance for companies in the Maintenance for the Construction industry, and examine how they can be implemented using the powerful combination of Netsuite + NextService.

1. A Focus on Customer Service

Fulfilling customer expectations is vital for building long term relationships in any industry. In the Maintenance for the Construction industry, this means ensuring that timely preventative maintenance (PM) is provided in order to limit the chance of problems arising. NextService automates the PM process by tracking equipment service history and allowing managers to allocate the required maintenance tasks to different teams within their company.

2. Effective Scheduling to Improve the First Time Fix Rate

To ensure maintenance to machinery and sensor is performed efficiently, it is important that the technicians handling the task have the appropriate skills and equipment. The more often a company can get the job right the first time, the happier their customers will be with their service. The NextService Scheduler allows managers to view customer and job information alongside information about their technicians’ skills and equipment, making it easy for them to assign the right staff to the right project. The Scheduler even features an integrated map, allowing managers to view all their field staff geographically and optimise their task scheduling based on this information.

3. Investment in Inventory Prediction Technology

For companies in the Maintenance for the Construction industry, managing inventory effectively is a vital key to success. Without utilising technology in this area, human error can easily lead to costly mismatches in inventory levels and job requirements and greatly impact your overall productivity. The NextService mobile app allows for complete inventory management utilising a built-in barcode scanner. This makes it simple for companies to manage their supply and demand by viewing the analytics in real-time.

4. A Focus on Accounting and Asset Management

Servicing machinery involves a lot of equipment, and as a result maintenance companies are required to manage the finances on a large number of assets. This can be extremely difficult and often results in confusion around the value of these assets after depreciation, and when to retire them.

NetSuite supports companies to understand their asset lifecycle, by tracking relevant information and calculating depreciation schedules. This allows companies to greatly improve their management of assets through real-time accounting.

5. Consolidation of all Platforms to a Single Tool

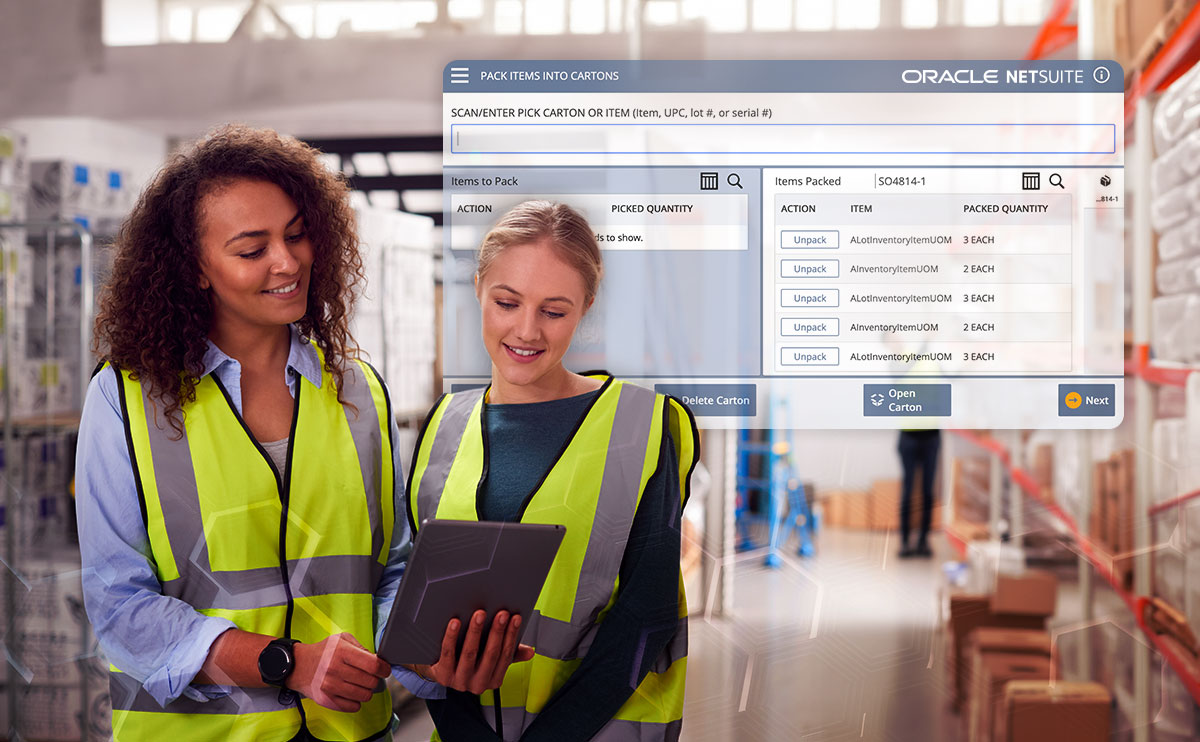

The Maintenance for the Construction industry is driven by data, and with so much relevant information to consider, it makes sense for maintenance companies to aim to store all this data in one place. Using multiple platforms with siloed information makes it difficult to get the complete picture, and increases the time spent by staff accessing and utilising information. NetSuite is an all-in-one business management tool, combining all the capability of CRM and sales tools with powerful accounting, inventory and project management automation. The platform integrates seamlessly with NextService providing companies with comprehensive control over both their admin and field operations.

It is clear that the coming years will present a lot of challenges to those in the Maintenance for the Construction industry, but opportunities arise as automation continues to drive increases to the efficiency of both the construction and maintenance processes. If you are a maintenance company looking to support your automation business within the industry, the combined NetSuite + NextService platform can assist you to improve your productivity by providing complete control over all your operations.

Utilising a single platform solution greatly simplifies your IT environment, empowering your team to work more effectively and giving you a real-time snapshot of your business.

Need a specialist’s free advice?

Feel free to call an expert in Enterprise Resource Planning Systems for Construction Providers today. Find out how cloud-based technology can support your subcontractor business and your addaptability strategies.